FEATURES & BENEFITS

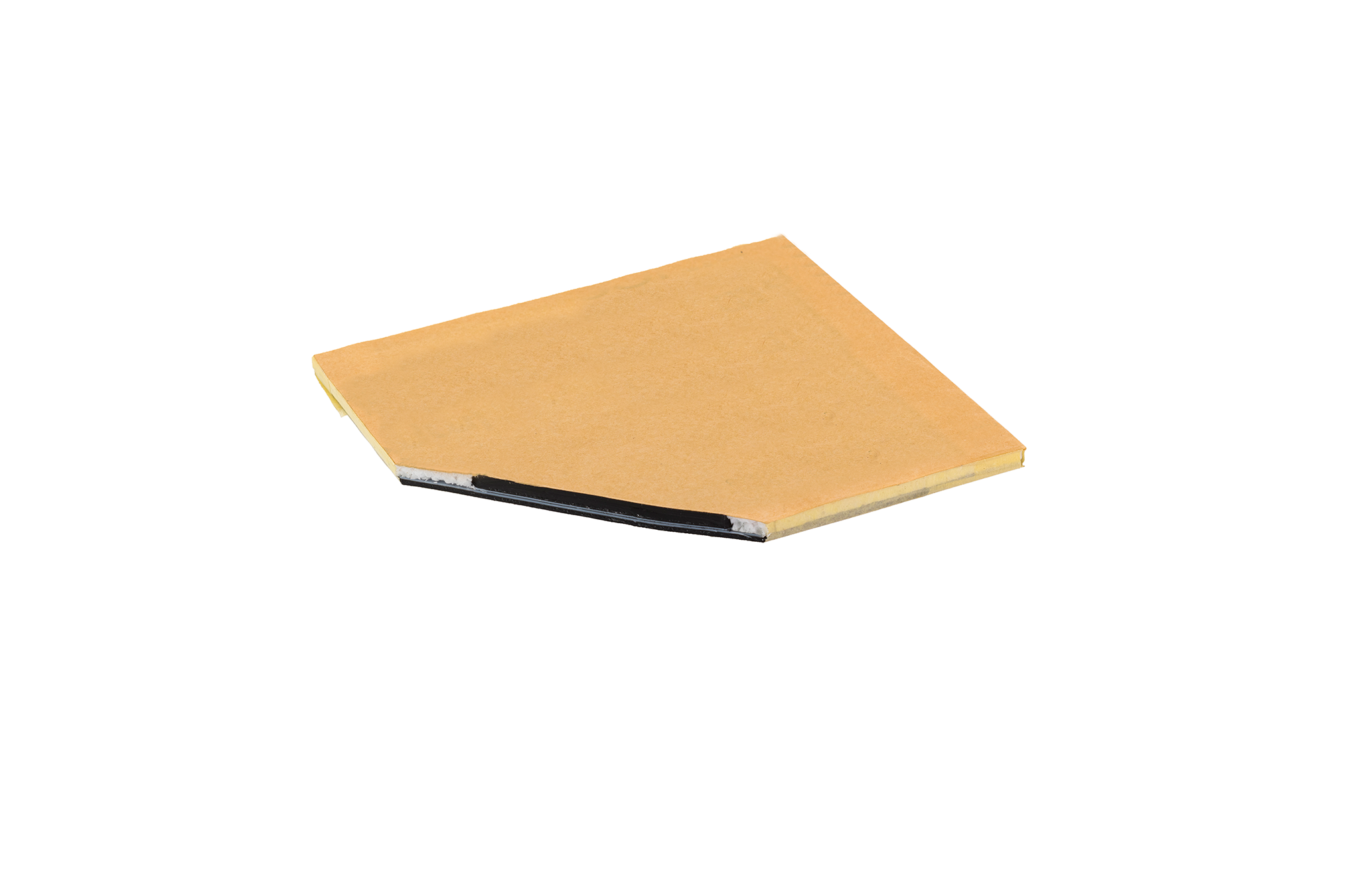

The rubber components allow for small irregularities in the bearing surface. The PTFE and elastomer are chemically bonded under heat and pressure. An expanded polystyrene surround to fit the supporting area is supplied, which locates the pads and assists in situ pouring of super-structure concrete. Bearings are protected from wet grout and concrete by a waterproofed backing. The lubricated PTFE sliding faces give a very low coefficient of friction (in the order of 0.05).

When placed between steel or precast surfaces, SKS bearings come with no waterproof paper as indicated by SKS(NW). Non-standard types Include holes and slots for bolts. In these cases, the load capacity of point load bearings is reduced, and contact must be made with the Technical Department.

The neoprene rubber compound is specially formulated to satisfy BS 2752 and reinforced with high quality warp knitted polyester fabric. The PTFE is Grade A to BS 3784 and lubricated with silicone grease. If an adhesive is used it should be non-solvent based.

01223 835623

01223 835623