FEATURES & BENEFITS

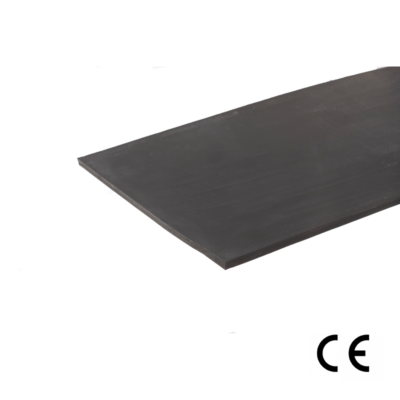

SKE-Type B Laminated Elastomeric bearings comply to the latest Eurocode EN1337-3. The bearing is made of a specially formulated natural rubber compound, which is seperated by steel reinforcement to achieve the desired performance. The reinforcing plates in the bearings are chemically bonded to the elastomer which prevents any relative movement between the steel/elastomer. The hot vulcanization process is carried on, equally distributed between the rubber and steel layers and this is cured under uniform heat and pressure. Natural rubber has a good resistance against the change in temperature and other parameters such as the ozone, UV and a number of other chemicals.

Steel Reinforced Elastomeric bearings are designed to meet ultimate limit provision and if they are designed for loads greater than 4000kN the size becomes larger. Overall thickness of such bearings depends on rotation and translation requirements, as these are achieved by deformation of elastomer and the sliding parts are completely avoided. There must be suitable distribution of compressive, shear and rotational stiffness within the bearing. Shape factor plays an important role to control stress in reinforcement and strain in elastomer by choosing the appropriate internal elastomer thickness. Elastomeric bearings are suitable for highway and railway bridges, as translation and rotation may occur about either axis where translation direction is not defined.

Each SK laminated elastomeric bearing is subjected to ‘quick production test’ before dispatch to site. Compression and shear tests can be carried on bearings if a supporting test certificate is required. Strict quality control on every material and manufacturing process is monitored for complete traceability. A design service is also available to assist engineers in selecting standard and non-standard sizes of laminated elastomeric bearings.

01223 835623

01223 835623